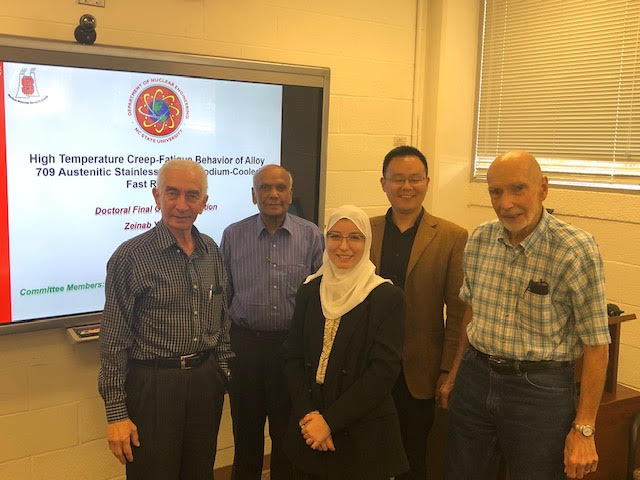

On March 9, Zeinab Alsmadi successfully defended her PhD dissertation, High Temperature Creep-Fatigue Behavior of Alloy 709 Austenitic Stainless Steel in Sodium-Cooled Fast Reactors. Zeinab ’s committee consisted of her advisor, K.L Murty and members, Ge Yang, Mohamed Bourham, and Ronald Scattergood.

Abstract

ALSMADI, ZEINAB YOUSEF. High Temperature Creep-Fatigue Behavior of Alloy 709 Austenitic Stainless Steel in Sodium-Cooled Fast Reactors. (Under the direction of Dr. K.L. Murty).

Generation IV (GEN IV) nuclear reactors are an important source of base load power in the middle–long term (2030–2050) and are designed to be safer, more reliable, more efficient and have longer lifetimes (60-80 years) than current nuclear reactors. The only possible mid-term available fast reactor is Sodium-Cooled Fast Reactor (SFR) with an acceleration in research and development along with reduction in economic competitiveness. However, the design and operation of SFR exhibiting cyclic thermal stresses during start-ups and shut-downs introduce time-dependent effects like creep during on-load periods leading to creep-fatigue interaction in many of the reactor components. Therefore, the structural material of SFRs should have excellent mechanical properties that can withstand the harsh operating environments. Fe-25Ni-20Cr austenitic stainless steel (Alloy 709) is developed for boiler tubing and high-temperature applications such as SFRs and ultra-supercritical (USC) power plants due to its adequate mechanical properties. Thus, it is important to understand the creep-fatigue interaction of Alloy 709 in order to generate enough data in a reasonable time and extrapolate them to the service conditions expected in SFRs.

To establish fatigue characteristics of Alloy 709, strain-controlled low-cycle fatigue (LCF) tests were performed at strain ranges from 0.3% to 2.5% at 750 °C and 2×10-3 s-1 strain rate (0.1 Hz). It is found that the predicted fatigue life of Alloy 709 shows a better correlation with the characteristic slopes method rather than the universal slopes method.

To investigate the effect of hold time on high-temperature creep-fatigue behavior of Alloy 709, strain-controlled creep-fatigue tests were performed with hold times of 60, 600, 1,800 and 3,600 seconds introduced at the maximum tensile strain at 1% strain range at 2×10-3 s-1 strain rate (0.1 Hz) and 750 °C. The creep-fatigue life of Alloy 709 and the number of cycles to macro-crack initiation are found to decrease with increasing hold time indicating faster crack initiation and higher growth rates. The fractographs of the deformed samples at 1% strain range with no hold time indicated that fatigue is the dominant mode of deformation whereas for the samples deformed at the same strain range with different hold times, both fatigue and creep have contributed to the overall deformation of the alloy.

The effect of strain range on high-temperature creep-fatigue interaction of Alloy 709 is investigated by conducting strain-controlled creep-fatigue tests with tensile hold times of 0, 600, 1,800 and 3,600 seconds at strain ranges varying from 0.6% to 1.2% at 750 °C and 2×10-3 s-1 (0.1 Hz) strain rate. In general, with increasing strain range at a given hold time, the number of cycles to failure decreases until saturation. The fractographs of the deformed samples exhibited increased number of cracks with increasing strain range along with Cr23C6 precipitates and high dislocation density.

Finally, the effect of temperature on creep-fatigue behavior of Alloy 709 is investigated by conducting strain-controlled creep-fatigue tests with tensile hold times of 0, 60, 600, 1,800 and 3,600 seconds at 1% strain range at 650 oC and 2×10-3 s-1 (0.1 Hz) strain rate. It is found that the number of cycles to failure at 650 oC is higher than that at 750 oC, and the material exhibits fluctuations in the number of cycles to failure at 650 oC due to the effect of Dynamic Strain Aging (DSA). The fractographs of the deformed samples exhibited increased density of cracks and creep cavities at higher temperatures along with Cr23C6 precipitates and high dislocation density. Furthermore, creep-fatigue life is evaluated by linear damage summation (LDS) of cyclic and creep damage fractions according to ASME code and creep-fatigue interaction diagram of Alloy 709 is constructed at different strain ranges, temperatures and hold times.